BMW starts series production of electric motors for the Neue Klasse

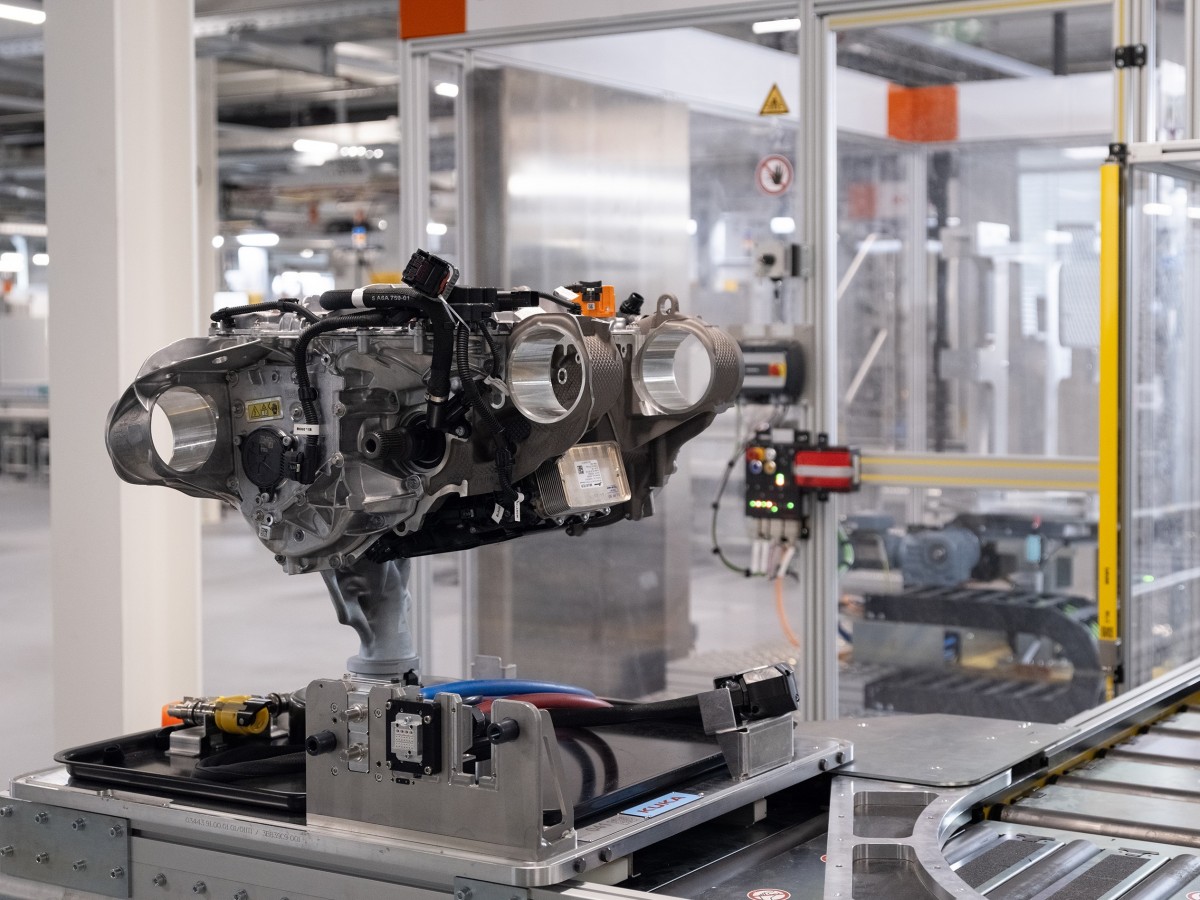

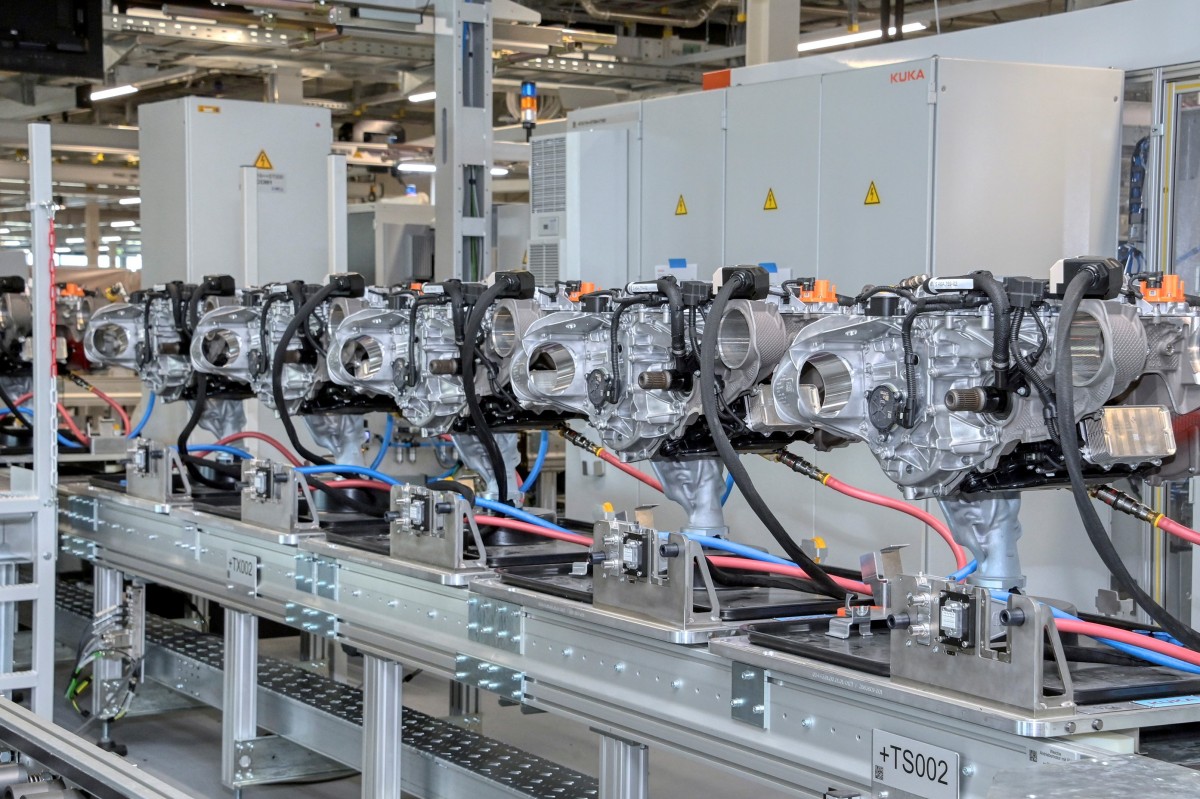

Today, BMW has proudly announced the start of series production of the electric motors it will use in the Neue Klasse. These 'Gen6' motors will be made at the company's plant in Steyr, Austria, at least initially - the facility is said to be "the first production site" for them, not the only one.

Once made in Steyr, they will be shipped throughout BMW's production network. BMW originally announced that it was going to build the electric motors in Steyr three years ago, and now it's finally delivering on that promise.

Until 2030, BMW will have invested over $1 billion in the Steyr plant for the purpose of development and production expertise related to these motors. Thus, it will remain the BMW Group's leading location for drivetrains.

The plant has made ICE engines for BMW and Mini for 40 years, and now it's stepping into its new chapter, while continuing to make petrol and diesel engines in parallel. Around 1,000 employees will work in the new electric motor assembly. BMW says half of the Steyr facility's total workforce could be employed in e-mobility by 2030, "depending on global demand".

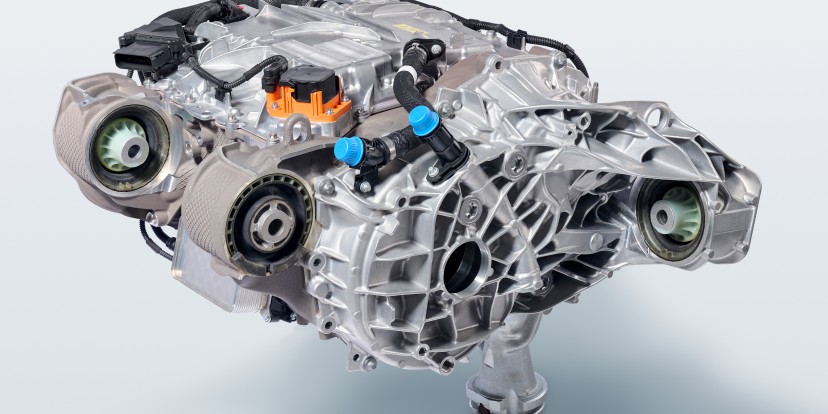

The plant will manufacture the rotor, stator, transmission, and inverter, all integral parts of the electric motor (which uses 800V architecture). The housing for the motor will be cast in Landshut, Germany, and further processed in Steyr.

The inverter will be produced in a new in-house clean-room environment, and the entire production concept for the Gen6 motor is modular, making it possible to produce different motor derivatives for the entire range of BMW Neue Klasse models.

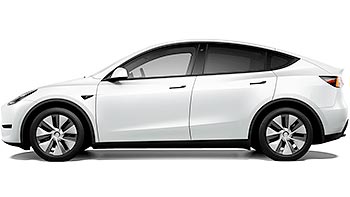

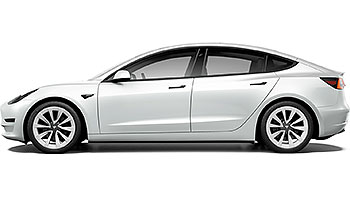

The next-gen iX3 50 xDrive will be about 20% more efficient than a Gen5 xDrive model, thanks to the new powertrain. When combined with a new high-voltage battery, this will enable a range of up to 497 miles WLTP in the iX3 50 xDrive, the first Neue Klasse model coming.

Related

Reader comments

Nothing yet. Be the first to comment.