The US can’t get lithium fast enough - Canada may have the answer

As the electric car adoption speeds up and breaks new records, the raw material suppliers are ringing alarm bells all over the world. Politicians set up ambitious goals, manufacturers promise new cars and new technologies. The emissions-free future seems certain, if we believe the general narrative. There’s only one little problem.

Yet, according to many sources from within the industry, we simply don’t have enough lithium to support the transition rate at that pace. Well, there may be enough lithium on the planet, but we simply can’t get it out fast enough. We can’t process enough of it at those rates either.

The stark realization is setting in, new rules and incentives agreed by many governments around the world, designed to help the transition to electric cars - will most likely make things worse. Take the new US federal EV tax credit - it offers up to $7,500 discount for the buyer of a new EV, as long as the car is made in the US or a country the US has a free-trade agreement with. And as long as its battery is made from raw materials sourced from North America.

Open cast lithium mining

Open cast lithium mining

According to CEO of Piedmont Lithium, Keith Phillips, it means only a small number of cars will qualify for the tax credit. He explains that eventually the supplies and processing will improve, but there is literally no chance to meet all the demand right now or for the near future. Meeting the 2030 electric car production goals is simply impossible, according to Mr Phillips, he claims there is simply not enough lithium production capacity in the whole world.

The lithium production is not just about lithium itself, while we may have enough of the raw material, there is much more to it. Piedmont Lithium for example is building two more processing facilities in the US, one in Tennessee scheduled for opening in 2023 and one in North Carolina the year after. The issue here is bureaucracy - the permitting process that simply stifles progress.

While the US is struggling to organize itself with a lithium processing facility taking as much as eight years to obtain government approval, China, Australia, Chile and Canada are speeding ahead. It takes less than a year to get all necessary licenses in Australia with other countries taking about a year as well.

Snow Lake Lithium has big plans

Snow Lake Lithium has big plans

Canada seems to be on a roll in the current market, while the US is scrambling for local resources and processing sites, Snow Lake Lithium announced it will deliver enough lithium to power 500,000 cars every year for the next ten years.

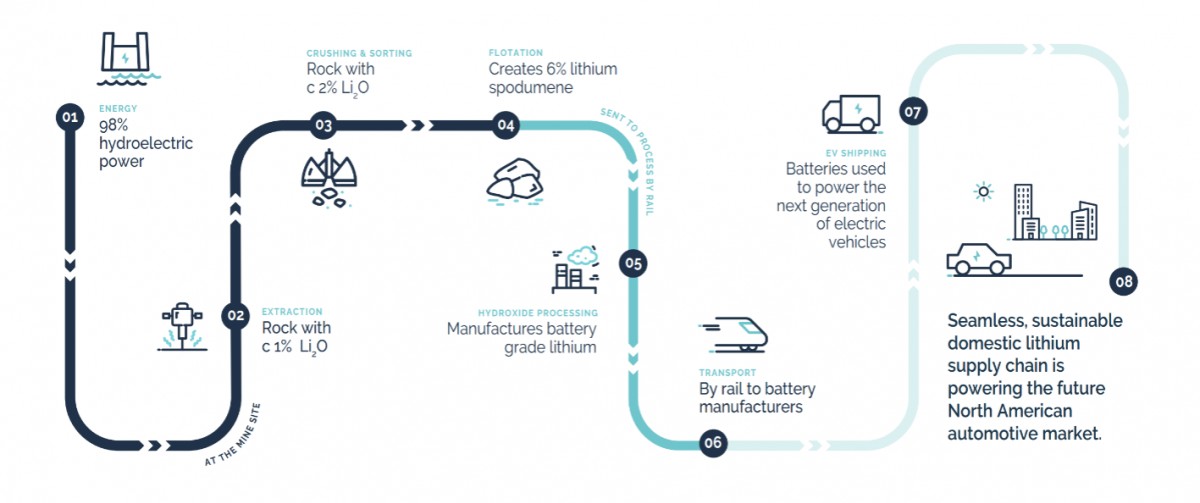

The company has access to one of the richest lithium supplies in North America and wants to process it locally rather than shipping it raw all over the world. The mining and processing will use exclusively electricity supplied by hydropower, all mining equipment is powered by electricity and even material shipping will be done by light rail system rather than conventional road transport.

Snow Lake Lithium wants to be a “no-harm” lithium manufacturer, the company uses hard-rock mining rather than brine pool extraction which it claims is far more environmentally friendly.

Snow Lake Lithium plans to be a "no harm" lithium producer

Snow Lake Lithium plans to be a "no harm" lithium producer

Thanks to the new EV tax credit rules, the company is positioned strategically to become a major lithium supplier for automakers wanting to take advantage of the new qualifying rules. Germany is far ahead of the competition with VW and Mercedes already having signed cooperation agreements with the Canadian government for lithium supplies. Hyundai is apparently not far behind with its search for Canadian raw materials suppliers as well.

We have ambitious goals already set into legislation, which puts a lot of onus on every automaker out there. The initiative is simply awesome, going electric makes sense for so many reasons, lack of direct emissions is just one of them. But it seems the decisions were hasty and the rapid transition may mean, if there is no proper oversight, that corners will be cut to achieve the legal requirement.

Over and over again, we learn from history that we aren’t that good at sensible decision-making in rapidly changing environment. While there is a clear urgency to cut our emissions - because lowering them no longer works - we may have focused on the outcome without thinking how to get there without making more mess.

500,000 batteries per year for next ten years may not be enough

500,000 batteries per year for next ten years may not be enough

It all will be worked out, there will be mistakes and there will be consequences. In a short run it means we, the customers, will pay a lot more for our cars despite all the incentives out there. We have new battery tech making headlines every day, battery companies are already looking for lithium replacements that are cheaper and less harmful. If we can diversify quickly enough, we will achieve the transition to electric cars fairly quickly. It won’t be 2030 or even 2035, but it’ll be close enough.

Related

Reader comments

Nothing yet. Be the first to comment.