Dongfeng's new solid-state battery promises 1,000-kilometer electric cars by 2026

The "ultimate" electric car - it's a promise that has been dangled in front of us for years, always just out of reach. Drivers want EVs that can travel as far as a gasoline car on a full tank, charge in minutes, and not lose half their power when the temperature drops. It sounds simple, but it's far from being easy.

The two biggest issues for electric cars have always been range anxiety - the fear of running out of power - and the long wait at a charging station. But a Chinese automaker, Dongfeng Motor, claims it is on the verge of solving both problems. At the 2025 World Power Battery Conference, the company announced aggressive plans for a new solid-state battery and a matching high-speed charging platform.

The centerpiece of Dongfeng's plan is its new solid-state battery. Solid-state technology removes the liquid component (the electrolyte) and replaces it with a solid material. This change is key to unlocking better safety and energy storage. Dongfeng says it has already completed and is operating a 0.2 GWh pilot production line for these new cells.

The company is targeting September 2026 to begin mass production of the battery, which has an energy density of 350 Wh/kg. For the average driver, this number translates to one thing: range. Dongfeng estimates that electric cars using this battery will be able to travel up to 620 miles on a single charge. This suggests that if we assume average EV efficiency to be about 180 Wh/km, the battery would have the capacity of around 180 kWh, and it would weigh just over 1,102 lb.

But apart from the impressive range, this new battery technology addresses two major weak points of current EVs: performance in extreme cold and safety. Dongfeng's battery uses a high-capacity ternary cathode, a silicon-carbon anode, and a special oxide-polymer composite solid electrolyte. This chemical recipe allows the battery to perform exceptionally well in freezing weather.

Dongfeng's tests show that even at a frigid -22°F, the battery keeps over 72% of its capacity. This is a big improvement over mainstream liquid-based batteries, which typically retain only about 60% in similar conditions. The solid-state design also makes the battery much safer. In thermal safety tests, the cell passed a 338°F hot-box test, a temperature that would cause many conventional batteries to fail. This is well above China's national standard of 266°F, giving a much wider safety margin.

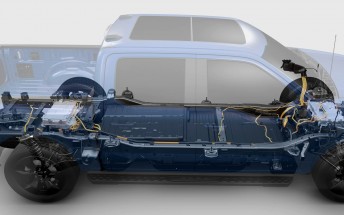

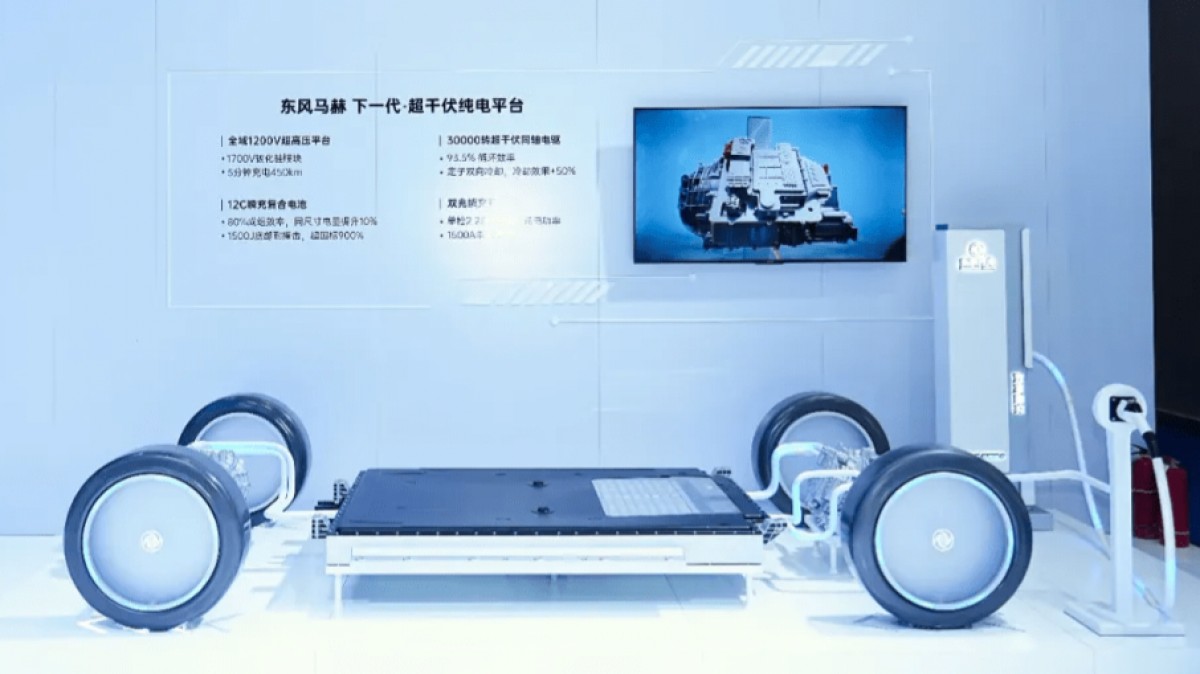

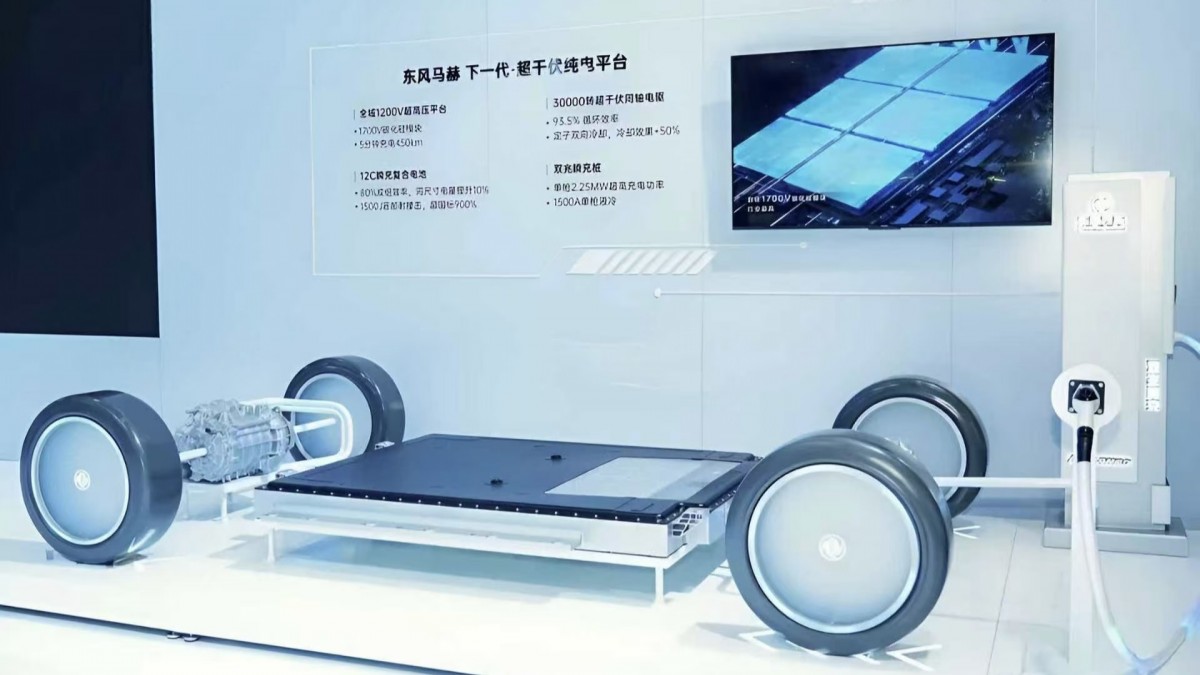

A revolutionary battery is only half the battle, and it needs a car platform built to handle its power. Dongfeng also revealed its new "Mach Ultra-kV platform," a 1,200V ultra-high-voltage architecture. This system is the backbone for the next generation of Dongfeng EVs, and it uses a powerful, in-house-developed 1,700V silicon-carbide (SiC) power module.

Silicon carbide is a special material that is much more efficient at handling high voltage and power than traditional silicon, reducing energy loss and allowing for faster charging. The platform also features a high-speed coaxial drive system with a motor that can spin at a dizzying 30,000 rpm. This advanced motor and the high-energy-density battery pack work together to achieve what Dongfeng calls a "real-world range" of over 1,000 kilometers.

Perhaps the most exciting part of the new platform is its charging capability. The 1,200V system and its 12C ultra-fast-charging cells are designed to absorb power at incredible speeds. The platform can support charging up to 2 MW from a single charging gun. Dongfeng's marketing claims are bold: "1 second of charging for 2.5 km of range."

A more practical and astounding figure is the ability to add 280 miles of range in just 5 minutes. That is less time than it takes most people to order a complicated coffee, effectively matching the convenience of a gasoline fill-up. Dongfeng is also integrating automated charging and seamless, contactless payment functions to make the process even easier.

Dongfeng has also built several safety features directly into the new platform. The battery pack is designed with 1,500 J impact resistance to protect it during a crash. The system also includes a 48-hour thermal-runaway early-warning system, which monitors battery health and alerts the driver long before any heat-related issue becomes critical.

The fast-charging version of the 350 Wh/kg battery is planned for pilot vehicle installation in December 2027, and research has already begun on a next-generation sulfide all-solid-state battery targeting a massive 500 Wh/kg energy density.

Related

Reader comments

- shawman123

cnevpost article on it mentioned its semi solid state or Solid/liquid battery as China wants to call it. Take everything with a huge grain of salt until we have production cars on road.

- 18 Nov 2025

- 8vm

- Anonymous

What? Are you saying they are not paying for It?

- 15 Nov 2025

- Jyx

- Anonymous

china steal all their nickel from Indonesia, colluding with the most corrupt government in the world!!

- 15 Nov 2025

- txG