Audi betting big on AI to improve production efficiency

Even though Audi isn't at the forefront of the autonomous driving revolution, the company is betting big on AI when it comes to production. In its moderately lengthy recent press release, the company shared some of its behind-the-scenes AI projects and how they helped boost quality control, efficiency and creativity.

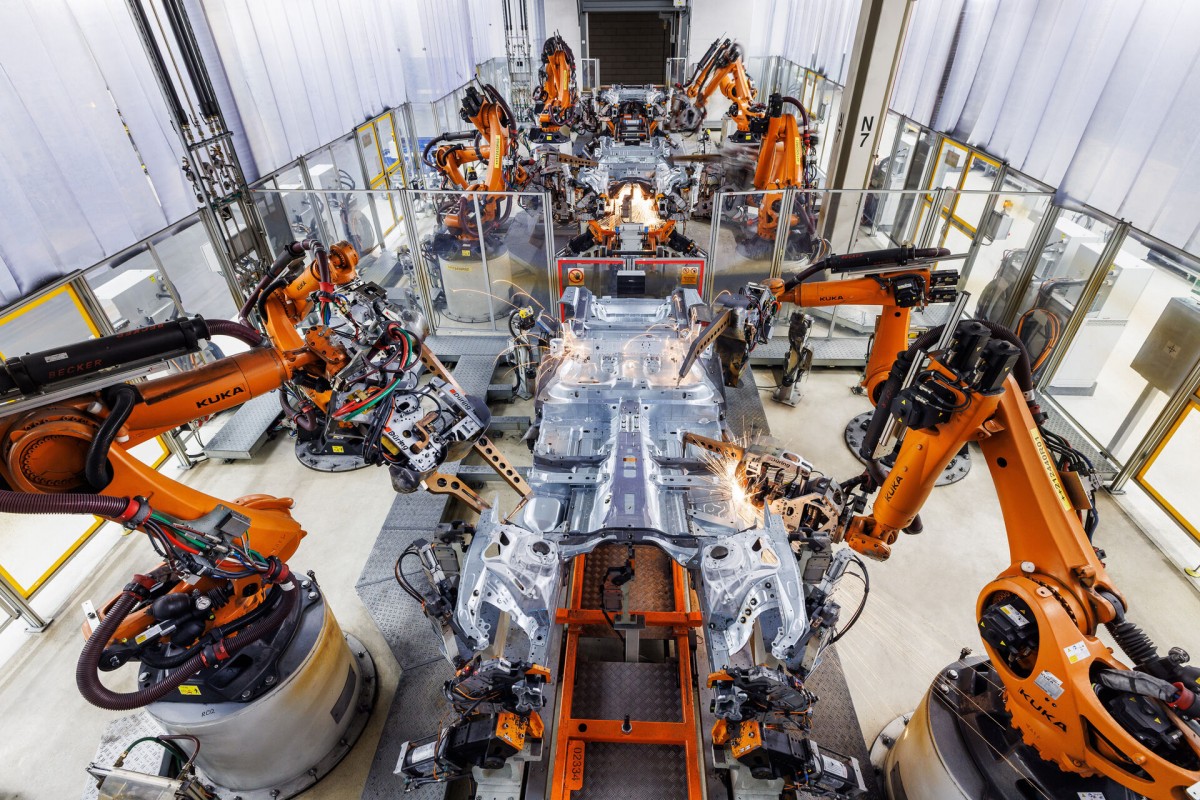

Audi says it has more than 100 AI projects in development used in various stages in its production facilities. The carmaker also started gradually implementing some of those AI-powered processes.

For instance, Audi is leveraging AI's capability to process huge datasets, helping with organization and efficiency at the company's huge data centers. Data production is the biggest dataset in the company, and AI is helping Audi achieve "360factory" - a data-driven factory.

The "Tender Toucan" boosts employees' time efficiency by 30% during the tendering process. The AI tool will see a wider rollout this summer to help with the series production planning of drivetrains and batteries.

IRIS and WSD are vision-engine AI tools that help employees with quality control, inspecting various elements around the car, saving one minute per production vehicle. Audi even joined forces with Siemens on the WSD (Weld Splatter Detection) tool, preventing potential future cable failures, for example. After a wider rollout this summer, a robotic arm will remove the detected weld splatter.

Audi is also working closely with IPAI (Innovation Park Artificial Intelligence) in Heilbronn. IPAI is also starting construction of Europe's biggest AI network, with Audi getting an office in the tech park.

Related

Reader comments

Nothing yet. Be the first to comment.