Analyzing the Mercedes-Benz EQXX revolutionary concept

One of the main criticisms that electric cars face is the limited range and the far slower recharge speed in comparison with ICE vehicles. The main reason for this, is the vastly lower energy content that their batteries carry compared to a fuel tank.

There are generally two ways to increase the range of any car. The simpler way is to increase the capacity of the fuel tank. This is normally easy and cheap for a fuel powered car, but quite the challenge and substantially more expensive when we are talking electric vehicles. The other way is to optimize all the aspects of the given car - from aerodynamics and rolling resistance to weight reduction.

Mercedes-Benz EQXX went 1,008km on just one charge, with overall 8.7kWh/100km energy consumption and with an average speed of 87 km/h. So Mercedes put in a big battery and made sure the entire vehicle is super efficient. Let’s dive into how exactly it pulled it off.

The Mercedes-Benz EQXX

The Mercedes-Benz EQXX

Aerodynamics

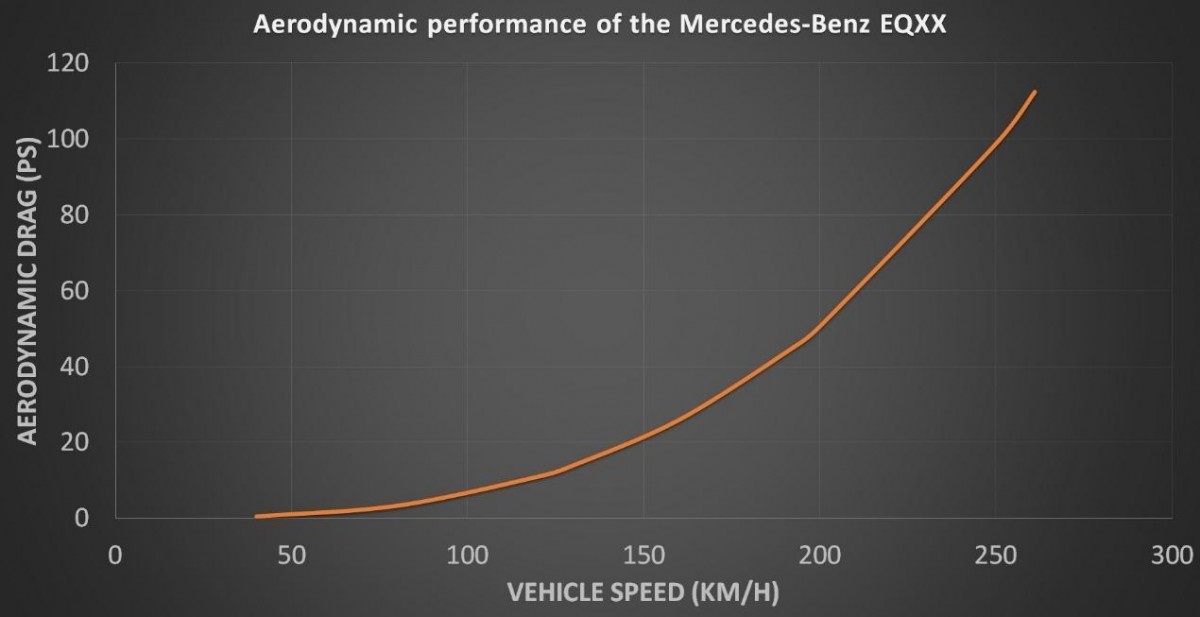

The number one energy consumer in any car is the aerodynamic drag. While at speeds below 60 km/h this drag is not that high, at a typical highway speed it is the most energy intensive aspect of a car. The Mercedes-Benz EQXX has a Cd value of 0.17 and frontal area of 2.12 m2. That means that the total drag area is 0.36 m2 which is extremely low. By comparison, Mercedes-Benz EQS, which is one of the most aerodynamically efficient cars currently on sale, has a total drag area of 0.5 m2 - 39% higher than that of the EQXX.

Wind tunnel testing of the Mercedes-Benz EQXX

Wind tunnel testing of the Mercedes-Benz EQXX

Mercedes-Benz achieved it through targeted measures. The general waterdrop shape, 50mm narrower rear part of the car, on-demand aero cooling, lengthening of the tail of the car and a combination of active and passive aerodynamics. The 20 inch wheels are totally covered to boost aerodynamic efficiency because they account up to a quarter of the total aerodynamic drag of a car. At 130 km/h, which is a typical highway speed, the power requirements of the EQXX because of these measures are just 14 PS, which is shockingly low.

At 130kmh the Mercedes-Benz EQXX needs just 14PS because of low aerodynamic drag

At 130kmh the Mercedes-Benz EQXX needs just 14PS because of low aerodynamic drag

Powertrain

Mercedes-Benz claims 95% powertrain efficiency - from battery to wheels, another highly impressive number. In the power flow between the battery and the wheels, we have three sources of energy loss. The power electronics, the motor and the gearbox. To achieve this kind of efficiency, each of these three sources must have an efficiency of over 98%, something not currently possible in the mainstream automotive industry.

We can make an educated guess regarding the motor though, which should be synchronous and more probably of permanent magnet type. The motor and power electronics, because of their very high efficiency, have very low cooling demands. The concept of on-demand (aero and liquid) cooling is used here to reduce aero drag and power requirements. The maximum power of the motor is 180kW (245PS) with the torque currently unknown but it should be around 400 Nm.

The compact powertrain of the EQXX

The compact powertrain of the EQXX

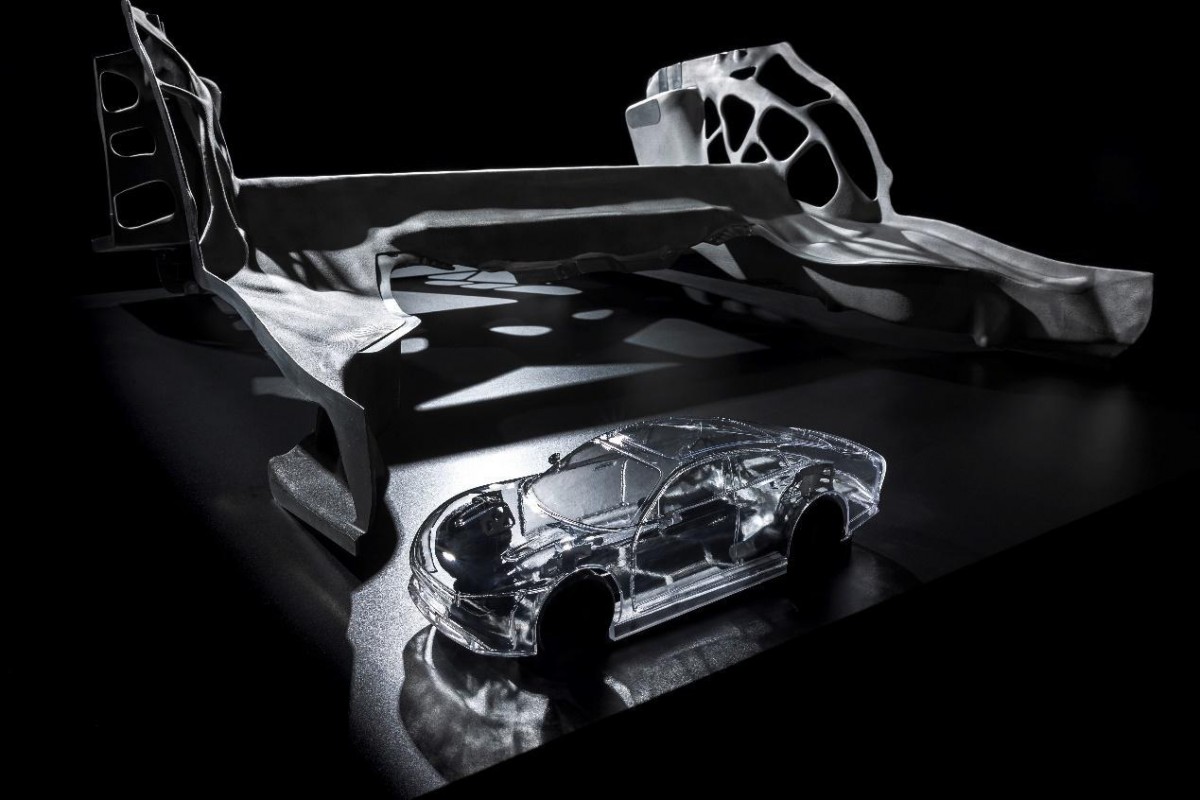

Bodywork

In the quest for efficiency, lightweight construction is mandatory. Even though electric cars have regenerative braking and the heavier they are, the more kinetic energy they harness, during a highway trip the regenerative braking is almost zero. The unladen weight of the EQXX is 1,755 kg which is a technical highlight by itself considering that the high voltage battery alone weighs almost half a tonne.

The EQXX is made of aluminum, martensitic steel and carbon fiber reinforced plastic, while the wheels are made from forged magnesium. For the first time aluminum brake discs have been used which are lighter than traditional steel discs.

The aluminum brake discs combined with magnesium wheels greatly reduce the unsprung mass of the car and improve the acceleration and ride comfort. All these materials are characterized by their lightness while maintaining high stiffness and rigidity.

In general, bionic principles have been adopted in the construction process and materials were used only where they were needed thus avoiding excessive usage. This philosophy expands in the car interior with sustainable and light materials used all around. To further improve vehicle efficiency, solar cells are used on the roof. These only utilized for the low voltage consumers such as the infotainment system, the air blower and LED headlights. On a bright day, they contribute up to 25km of range, which is pretty minor, but important when chasing records.

The rear aluminum construction of the EQXX

The rear aluminum construction of the EQXX

High Voltage battery

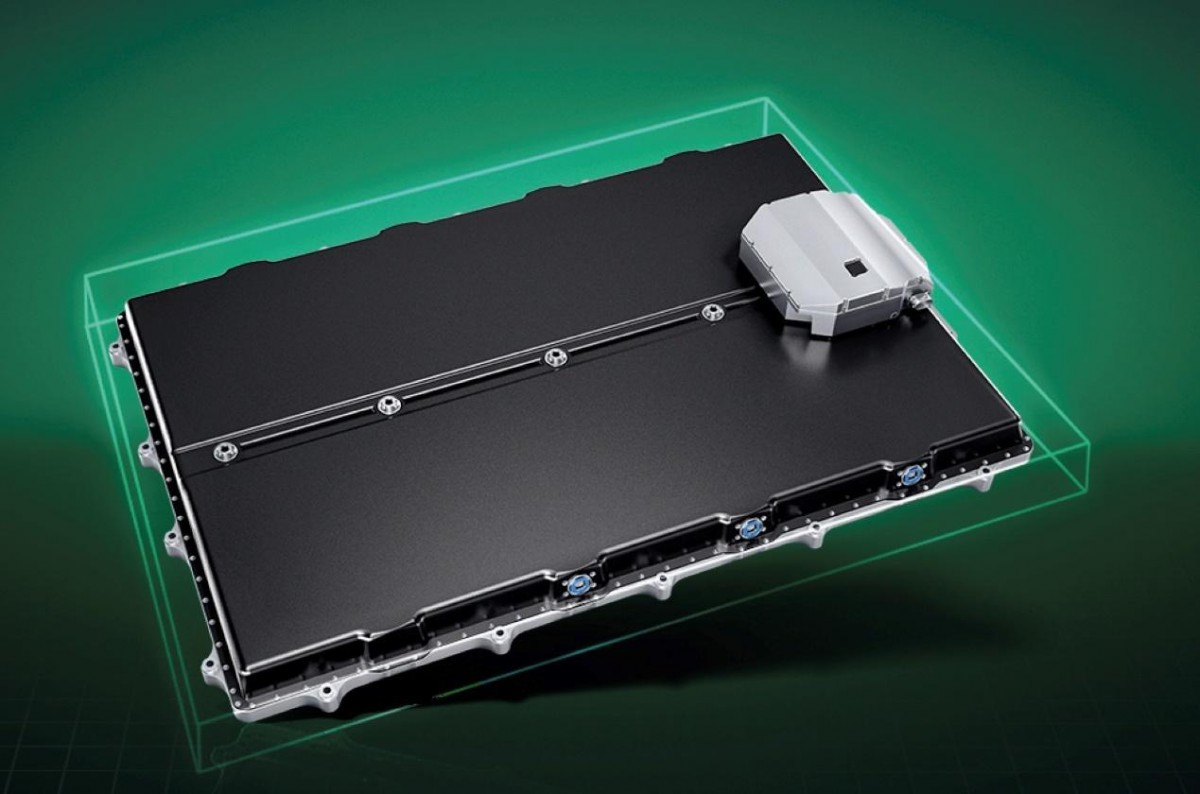

The high voltage battery that the EQXX uses has a net energy content of 100 kWh and weighs almost 500kgs. It uses cell-to-pack architecture (cells are not integrated in modules), it is air-cooled and has a carbon fiber top lid. All these features contribute to its low mass and compared to the high voltage battery used in the EQS, it is 30% lighter and occupies 50% less volume.

Another first for Mercedes-Benz is the >900V architecture. This high voltage value allows for superfast charging of the battery with supported DC chargers, although in this case, this wouldn’t be possible because of the passive air cooling that this battery uses.

In general it is possible to increase the electrical power through voltage or current. If we take the "current" approach there will be a weight and space penalty because of the thicker cables. That’s why it makes more sense to increase the voltage.

Mercedes-Benz has also used a different anode material compared to the EQS, with the EQXX integrating High-Silicon anode. The usage of High-Silicon anode helped to increase substantially the energy density of the EQXX’s battery to 200 Wh/kg, making it the most energy dense high voltage battery in the world. Using a carbon fiber lid and air cooling helped the battery to be fitted even in a compact car according to Mercedes-Benz.

Mercedes-Benz EQXX high voltage battery

Mercedes-Benz EQXX high voltage battery

The EQXX is just a concept but the technology used here could make it to Mercedes-Benz’s production cars in the coming years and this is very important for the establishment and dominance of e-mobility.

Related

Reader comments

- Jeffrey Kyle JACKSON

In future, cars will use Gravity Force to moving... Uranium is old era tech...

- 22 Sep 2025

- 64i

- Anonymous

Well, he is right.

- 30 Jul 2025

- JH2

- oo Ruly oo

Talking about concept and future car technology, isn't it better to use uranium as the fuel? I am bringing this topic because I remember correctly that everything now can be built smaller and way smaller. This would have chance uranium engine ca...

- 24 May 2025

- tDE