Tesla is scaling back on gigacasting ambitions

Tesla has reportedly hit the brakes on its groundbreaking gigacasting manufacturing process. Originally intended to create the entire underbody of new Tesla models from a single piece, anonymous sources familiar with the matter suggest the company will instead be opting for a more incremental approach. This news comes amid broader company cutbacks and a strategic shift away from rapid EV production growth and toward autonomous driving technology.

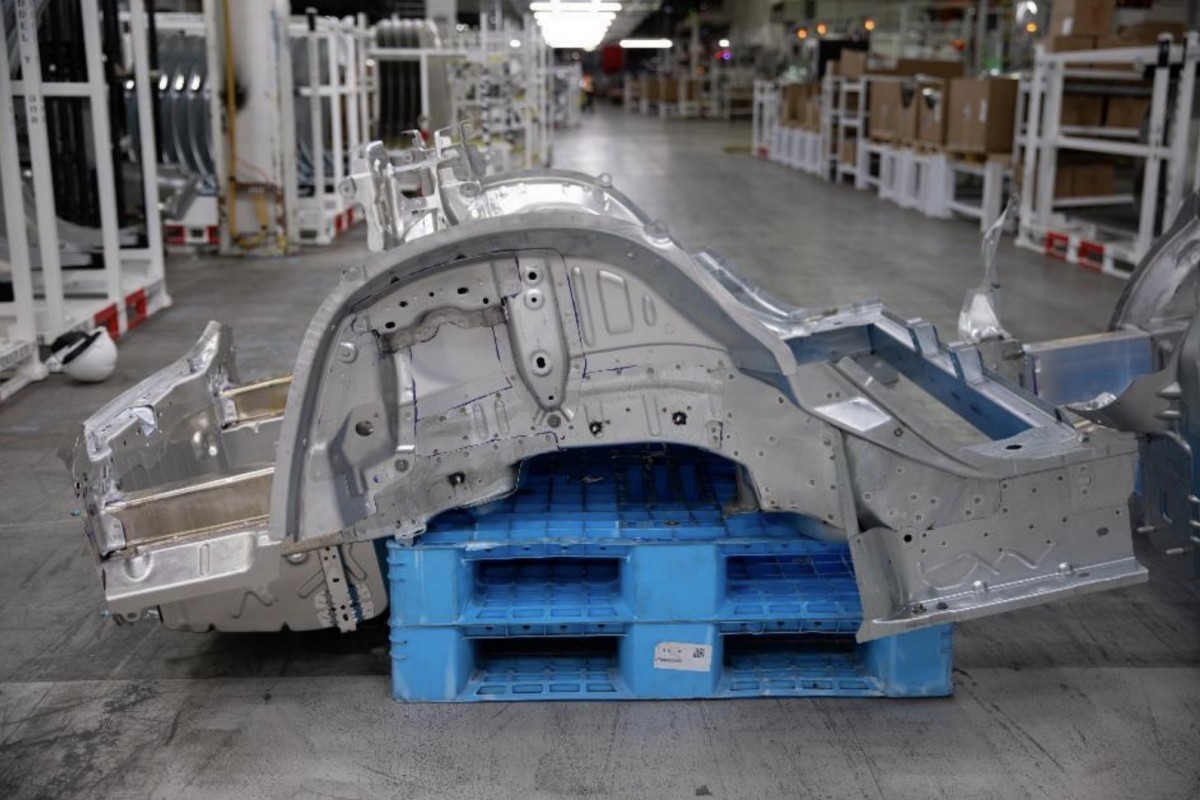

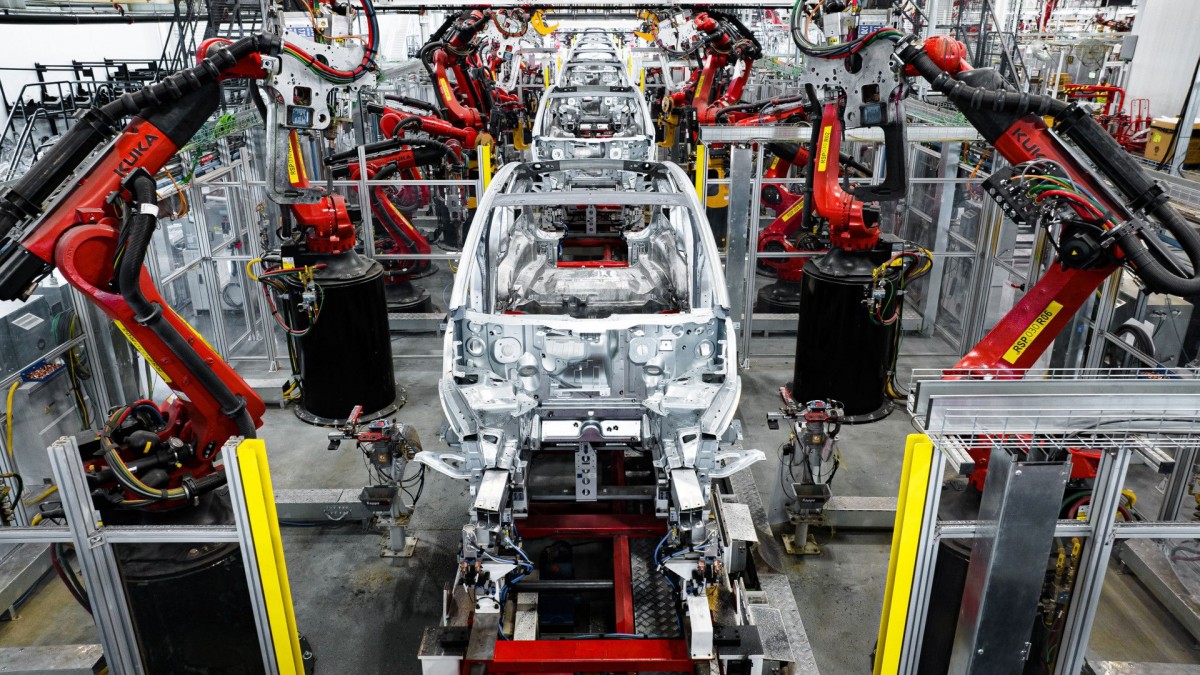

Gigacasting, a cornerstone of Tesla's innovation, simplifies vehicle production substantially. This process uses massive presses to cast large sections of a car's structure in single pieces, replacing the need for numerous smaller parts in traditional car manufacturing. Tesla currently uses gigacasting to create its Model Y and Cybertruck underbodies out of three components.

The initial plan for Tesla's next-generation gigacasting process was ambitious – to cast an entire vehicle underbody in one go. This would have streamlined production processes even further, with the potential for significant cost savings. However, it seems Tesla is sticking with its proven three-piece underbody construction technique consisting of two giant front and rear castings and a center section of aluminum and steel for battery storage.

The rationale behind this decision appears to center around cost control in the face of softening demand for EVs globally and heightened competition from other EV makers gaining ground in the market. The focus seems to be on developing autonomous driving technology rather than on increasing its EV production volume.

Last month, Tesla reduced its global workforce by over 10%, followed by several high-profile executive departures. These actions mirror the halt in development of its much-anticipated Tesla Model 2, an affordable EV slated for release in 2025 that was supposed to be the first showcasing the new one-piece casting method. In an earnings call last April, CEO Elon Musk hinted at a focus on cost optimization through simplified and accelerated production processes for more budget-friendly cars, although details remained scarce.

The focus on one-piece casting for Tesla's robotaxi program is ongoing. However, the decision to hold back on its consumer car application suggests the technology may still require extensive research and development before large-scale implementation. Automotive manufacturing experts acknowledge the high initial cost and technical complexity associated with gigacasting, especially considering Tesla's history of encountering delays with innovative vehicle launches

Related

Reader comments

The one piece gigacasting would probably have made insurance unaffordable due to even a small crash being a writeoff. Volvo had a similar problem at one point with a bidy design that wrote off after minor sill damage. This is why sensible EV buyers...

- 06 May 2024

- 39C

- Anonymous

Tesla is scaling back to save its stock. Selling their stock makes money for them, not selling cars.

- 03 May 2024

- rRU