Ford to invest $5B in an effort to reshape the EV market

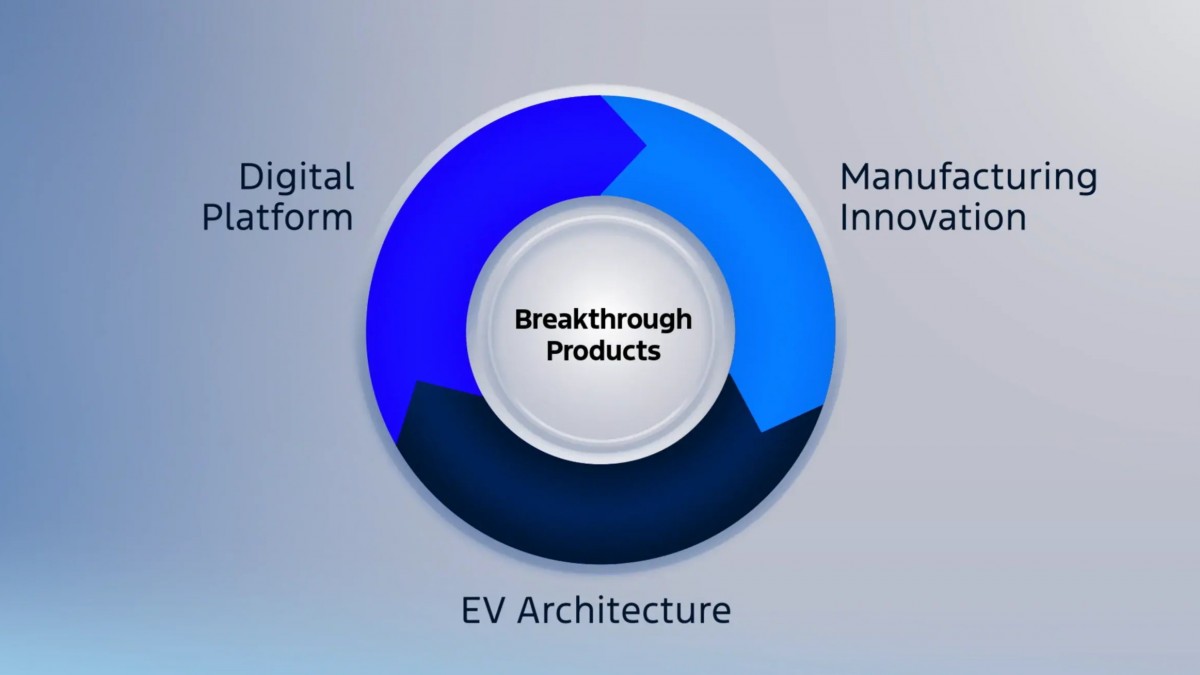

Ford is taking a dramatic new approach to the world of electric cars, and it all starts with a new midsize pickup truck planned for 2027. The company announced a brand-new vehicle platform and manufacturing system designed from the ground up to do something that has so far eluded most automakers: build profitable, affordable, and desirable EVs for the mass market.

To tackle this challenge, Ford created a small, independent "skunkworks" team based in California, far from its Detroit headquarters. The goal was to break free from traditional methods and solve old problems with new thinking. Detroit automakers have a long history of "good college tries" at building affordable small vehicles, often with disappointing results.

Ford hopes this new, focused team can finally crack the code by combining Silicon Valley-style innovation with its century of manufacturing experience. The mission is clear: create a family of EVs that customers love and that the company can build sustainably and profitably in America.

The foundation of this new strategy is the Ford Universal EV Platform. Engineers focused on simplicity to drive down costs and complexity. The new platform reduces the total number of parts in a vehicle by 20% and uses 25% fewer fasteners compared to a typical car.

A prime example of this simplification is the wiring harness in the upcoming truck, which will be over 4,000 feet (about 0.7 miles) shorter and 22 lb lighter than the one in Ford's first-generation electric SUV. This "less is more" approach is central to making these future electric cars more affordable.

A key piece of the puzzle is the battery. The platform uses lithium iron phosphate (LFP) prismatic batteries, free of both cobalt and nickel, making them less expensive and more sustainable. The battery pack will become a structural component of the vehicle, serving as the floor.

This integration lowers the vehicle's center of gravity for better handling, creates a quieter cabin, and frees up a surprising amount of interior space. This new approach to battery technology will be supported by Ford's BlueOval Battery Park in Michigan, which will begin producing the LFP batteries next year.

The first vehicle to use this new platform will be a four-door, midsize electric pickup. Ford is keeping specifics like price, battery range, and the exact reveal date under wraps for now, but it has shared some intriguing details. The truck is projected to offer more passenger room than a Toyota bZ4X. It will also feature a front trunk, or "frunk," and a lockable bed, providing versatile and secure storage.

Ford insists this won't be a stripped-down utility vehicle. The company is targeting a 0-60 mph time as quick as a Mustang Mach-E AWD, promising that the low center of gravity and instant torque from the electric motors will make it genuinely fun to drive.

The innovation extends to the factory floor. Ford is overhauling the traditional assembly line with a new concept it calls the "assembly tree." Instead of a single long conveyor, the vehicle is built from three main sub-assemblies that are put together simultaneously on separate lines before being joined.

The front and rear sections of the truck are made from large, single-piece aluminum castings, which replace dozens of smaller stamped parts. These two sections are then combined with the third major component: the structural battery pack, which already has the seats, carpeting, and center console attached. This new process is expected to be up to 15% faster and significantly improve ergonomics for assembly line workers.

Ford is investing nearly $2 billion to retool its Louisville Assembly Plant in Kentucky to bring its vision to life, securing 2,200 hourly jobs in the process. This investment, supported by the state of Kentucky, will expand the plant and upgrade its digital infrastructure.

Combined with a previous $3 billion investment in its Michigan battery facility, Ford is committing approximately $5 billion to its next generation of American-made EVs. It's a massive bet that this new philosophy of simple design and efficient manufacturing will finally put affordable, high-quality electric cars within reach for millions of drivers. Will it pay off? All we need to do is sit and watch, popcorn in hand.

Related

Reader comments

- supro

Better be 1000V platform or , with battery swap, if its coming in 2030. Other car makers are making $20k evs for 2030. If ford platform is 400v, $30k in 2030 it will be over priced, lower speced than competition , just like their current 2024 platfo...

- 13 Aug 2025

- rK8

- Anonymous

the presenters should do some exercise, like walking. the first two have pot bellies.

- 13 Aug 2025

- B4X

- Model T Moment

Glorious spare tire on the running board!

- 13 Aug 2025

- kmq