New breakthrough promises near-perfect EV battery recycling

Chinese scientists have developed a method to recover nearly 100% of the lithium from used batteries. This innovation addresses a crucial challenge in the growing EV market: how to handle the increasing volume of spent batteries in an environmentally responsible and cost-effective manner.

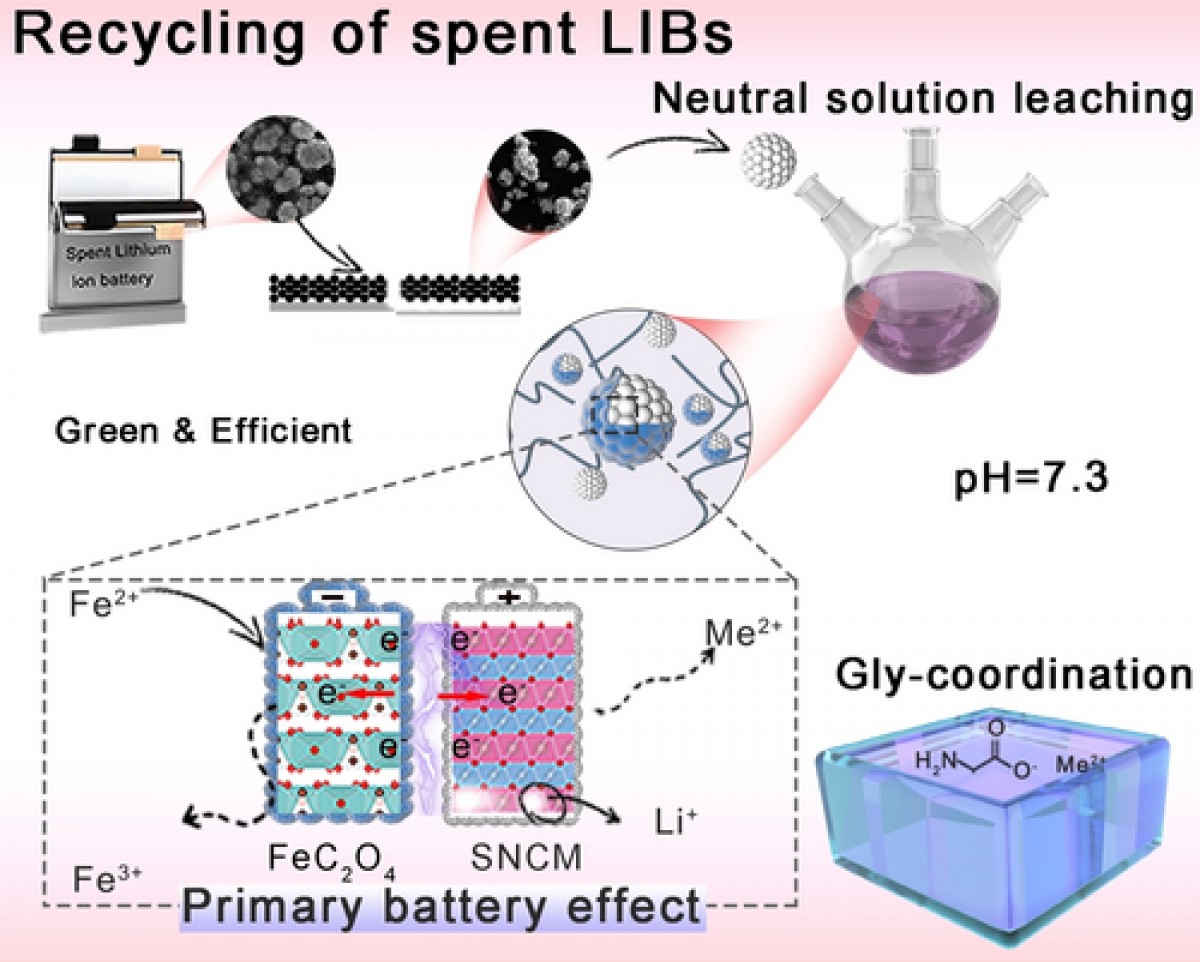

Researchers from several Chinese universities, including Central South University, have devised a "neutral leaching" technique that dramatically improves the efficiency of battery recycling. Unlike traditional methods that rely on harsh chemicals and pose environmental risks, this new process uses a neutral solution and the amino acid glycine. This approach allows for the extraction of 99.99% of lithium, 97% of nickel, 92% of cobalt, and 91% of manganese in just 15 minutes. This speed and efficiency are vital for processing the millions of EV batteries expected to reach their end-of-life in the coming decade.

The environmental benefits of this breakthrough are substantial. Traditional recycling methods often involve chemicals that can leak into the environment, causing contamination. The neutral leaching process minimizes the risk of harmful byproducts, making it a safer and more sustainable option. The reduced processing time translates to lower costs, making battery recycling more economically viable.

The timing of this innovation is critical. As the adoption of electric cars increases globally, so does the need for robust battery recycling infrastructure. In the United States, the battery recycling industry is expanding, with significant investments from both public and private sectors.

The Inflation Reduction Act plays a key role, as it treats batteries recycled in the US as American-made, regardless of their original manufacturing location. This incentivizes domestic recycling and reduces reliance on foreign supply chains. Even if political landscapes shift, the demand for batteries will persist, driven by various applications beyond electric vehicles, including hybrid cars, energy storage systems, and other technologies.

The advancements in battery recycling reduce environmental impact and have the potential to lower the cost of new EV batteries. By reusing valuable materials like lithium, nickel, and cobalt, manufacturers can reduce their reliance on raw material extraction, which is both expensive and environmentally damaging. This closed-loop life cycle approach to battery production is essential for the long-term sustainability of the electric vehicle industry.

Related

Reader comments

And slashing the budget of science and research won't make America great again...

- 22 Mar 2025

- n22

- Anonymous

China is at the forefront of developing new technologies, and this bothers the US.

- 21 Mar 2025

- Bin